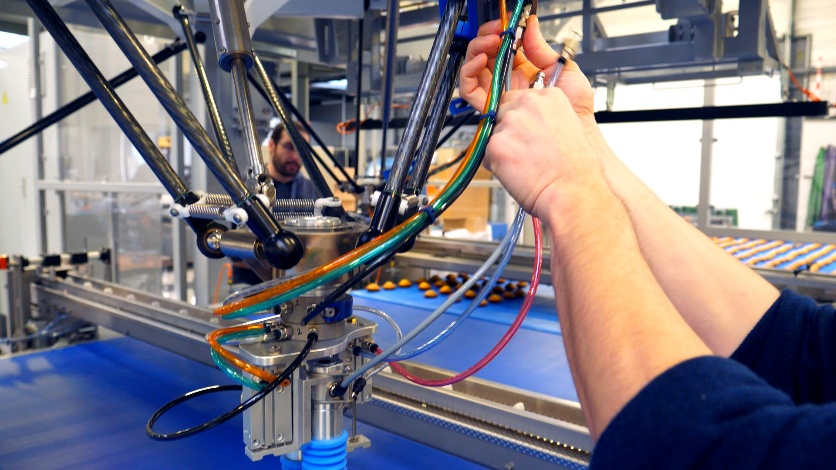

BFR Systems has expertise in several technologies, including ultrasound which offers better cut quality and greater precision. We offer ultrasonic cutting machines, exact or variable weight portioning, cubing, using either ultrasonic cutting or conventional blades.

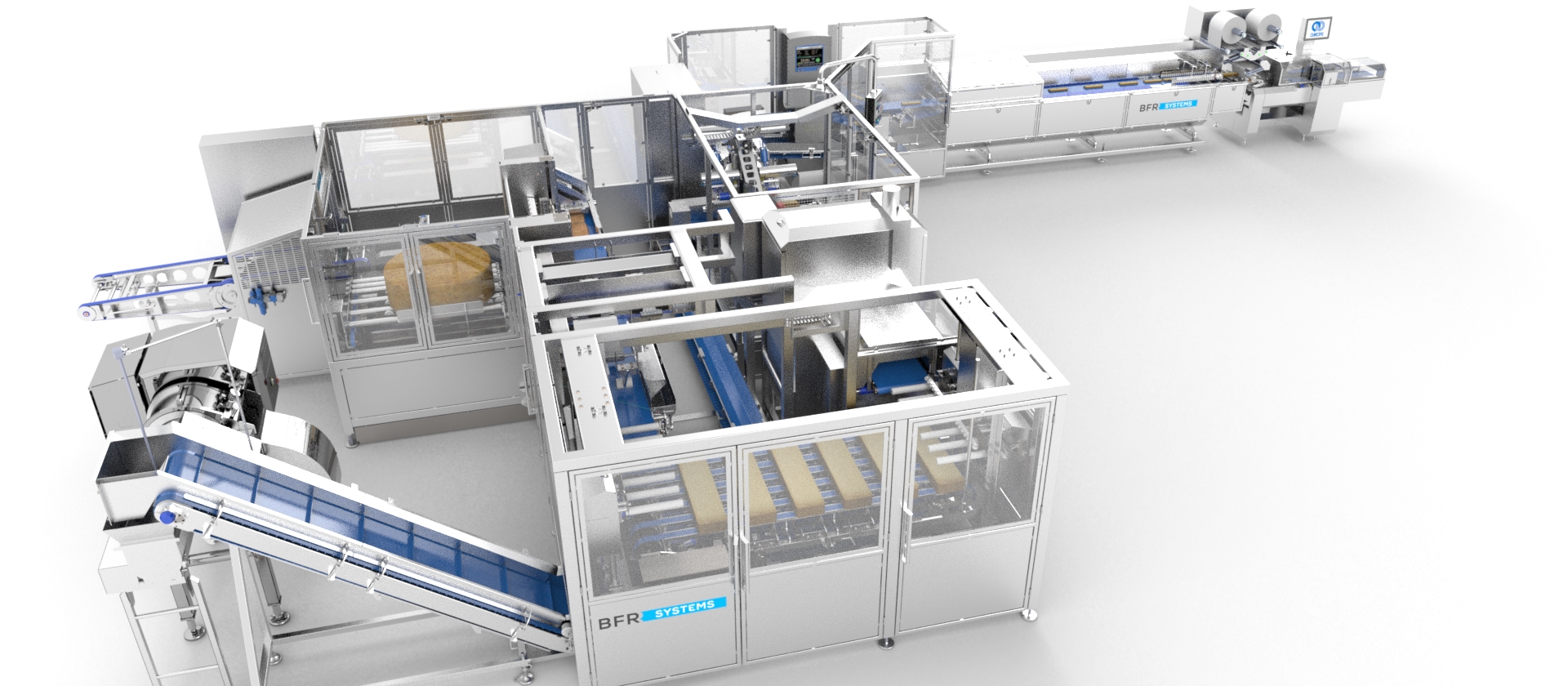

With 40 years of experience in cutting solution, our specialized team advises you on the possibilities of cutting. Working closely with you, we offer solutions that meet your needs. Our expertise in combining skills is a real asset that we have cultivated for many years. The group brings together the historical experience of several companies, each contributing their specific skills. Through the combination of in-house production of standard or custom equipment and distribution, we can meet the needs of all types of companies, from SMEs to the largest actors in the food industry.